Table of Contents

Introduction

In this article, I’ll give you the typical costs for various types of shingle roofs in 2025, including asphalt, wood, metal, synthetic, and slate shingles. I’ll also explain the factors that determine shingle roof costs.

Keep in mind that the cost of any particular shingle roof will depend on several variables, including roof size, roof pitch, roof complexity, local labor costs, and the type and quality of the shingles. The price of oil can affect asphalt shingle material costs, and metal prices can have a big effect on the cost of metal shingles.

On average, the cost of a shingle roof replacement in 2025 ranges from $5.60 per square foot for basic 3-tab asphalt shingles to $26.00 per square foot for high-end materials like copper or slate. For an average 1,700-square-foot roof, that puts the total cost of a shingle roof between $9,520 and $44,200, depending on the material.

Also see my Roof Replacement Cost Guide, which has typical current roof prices for other residential and commercial roofing materials.

Note on Average Roof Size

A precise value for the average roof size for existing U.S. single-family homes is not directly available from any official source. I used publicly available data for average home square footage and the percentage of 1-story versus 2-story homes, as well as adjusting for typical eave overhangs and an estimated average roof pitch multiplier, to estimate an average U.S. roof size of a little under 1,700 square feet.

Types of Roof Shingles

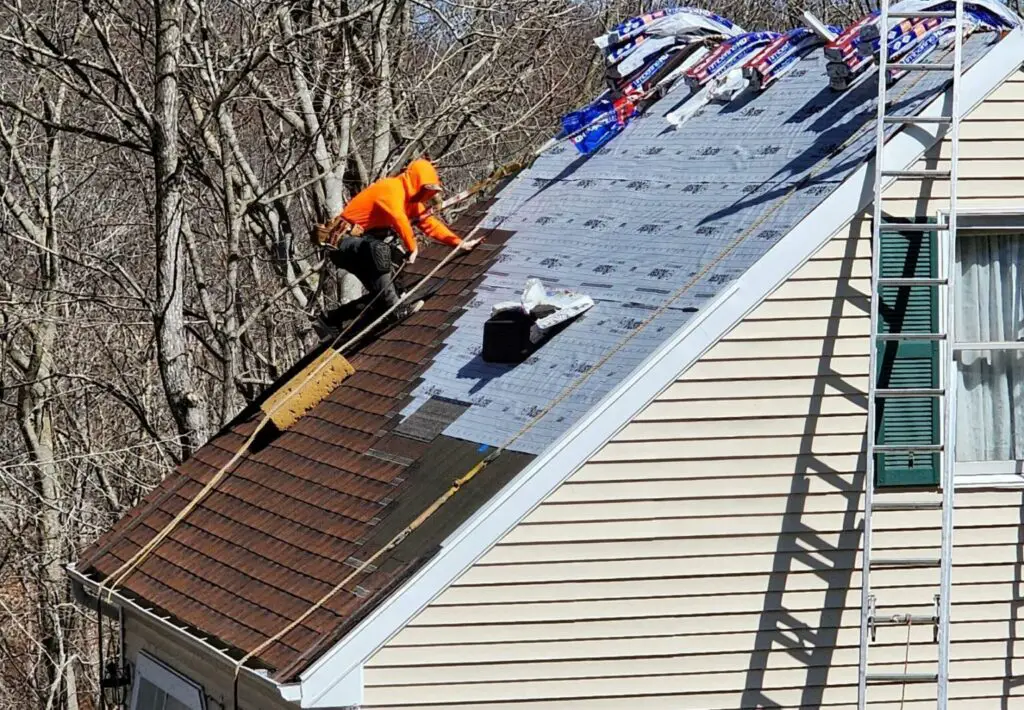

Shingle roofing is a broad category that includes any roofing system made up of small overlapping units installed in horizontal courses from the eave to the ridge. Shingles are typically installed over a solid deck with an underlayment and fastened with nails or screws, depending on the material. The individual shingles can be made from asphalt, wood, metal, slate, or synthetic materials, and each type has its own cost, appearance, lifespan, and installation method.

This article does not cover traditional clay or concrete tile roofing, which is similar to shingle roofing but generally recognized as a separate category for a few good reasons and will be covered separately.

Asphalt Shingles

Asphalt shingles are the most common residential roofing material in the U.S. They’re made from a fiberglass mat saturated with asphalt, further coated with layers of asphalt, and surfaced with ceramic-coated mineral granules. There are three main types: 3-tab (the cheapest and thinnest), architectural or dimensional (more durable and visually textured), and luxury (even heavier, with a high-end appearance). Asphalt shingles are relatively easy to install and repair.

See more detailed information about the cost of asphalt shingle roofs.

Metal Shingles

Metal shingles are relatively small interlocking panels, often stamped and painted to mimic the appearance of traditional materials like slate or wood. They are typically made from sheet aluminum, steel, copper, or zinc. Metal shingles are installed in horizontal courses using concealed fasteners. The bottom edge of each shingle hooks over the top hem of the course below, while only the upper edge is fastened. These fasteners are then covered by the next course. Side flanges allow the shingles to interlock with adjacent units, creating a continuous, watertight surface. Metal shingles offer excellent fire resistance, long-term performance, and resistance to high winds and hail. They cost more than asphalt up front but can last two to three times longer.

See more detailed information about the cost of metal shingles:

- Aluminum Roofing Cost Guide

- Copper Roofing Cost Guide

- Steel Roofing Cost Guide

- Zinc Roofing Cost Guide

Slate Shingles

Natural slate shingles are made from split layers of stone and are known for their durability and distinctive, stately appearance. A properly installed slate roof can last 75 to 150 years, but the material is heavy and expensive. Installation requires skilled specialized slate installers and the roof’s support structure (rafters, structural framing in general) must be able to support the weight, or be augmented prior to the slate installation so it can.

See more detailed information about the cost of slate roofing.

Synthetic Composite Shingles

These shingles are made from engineered polymeric materials and typically contain recycled plastics or rubber or both. They’re designed to replicate the look of slate, wood shakes, or other traditional materials while reducing weight and cost. Quality varies by brand, but many synthetic shingles offer good durability, impact resistance, and Class A fire ratings.

Wood Shingles

Wood shingles are typically made from cedar and offer a classic, natural look. Especially popular in New England and the Pacific Northwest, they weather to a silvery gray over time. Standard wood shingles are sawn for a smooth finish, while wood shakes are split for a more rustic appearance. They may require regular maintenance to keep them clean so they can dry out properly. They may be banned or restricted in some areas because they’re vulnerable to wildfire unless installed as part of a Class A fire rated system with special underlayment and wood treatments.

See more detailed information about the cost of cedar roofing.

Shingle Roof Cost in 2025

These cost estimates should be fairly accurate; I try to keep them reasonably up-to-date using current or recent material prices and labor data. Keep in mind that the costs listed below are national averages, and costs can vary quite a bit depending on location. To get a more accurate idea of what a new shingle roof will cost in your area, see “Relative Construction Costs by U.S. State” and apply your state multiplier to the national average cost given here.

The shingle roof cost estimates given below assume a roof with a 6/12 pitch (or less), include all standard roof components, and factor in the removal of the existing roof at $1.50 per square foot (which can vary). Steeper roofs or roofs with complex designs can increase labor costs by up to 50%.

Table: Shingle Roof Cost per Square Foot by Material Type

| Average Cost of a Shingle Roof | |||

|---|---|---|---|

| Shingle Type | Average Installed Cost Per Square Foot |

Average Installed Cost Per Square (100 sq. ft.) |

Average Installed Cost Average Roof (1700 sq. ft.) |

| Asphalt Shingles 3-Tab or Strip |

$5.60 | $560 | $9,520 |

| Asphalt Shingles Architectural or Dimensional |

$6.15 | $615 | $10,455 |

| Asphalt Shingles Luxury or Premium |

$7.65 | $765 | $13,005 |

| Metal Shingles (Aluminum) |

$14 | $1,400 | $23,800 |

| Metal Shingles (Copper) |

$26 | $2,600 | $44,200 |

| Metal Shingles (Steel) |

$10.50 | $1,050 | $17,850 |

| Metal Shingles (Stone-Coated Steel) |

$12.50 | $1,250 | $21,250 |

| Metal Shingles (Zinc) |

$18 | $1,800 | $30,600 |

| Slate Shingles Hard Natural Slate (Grade S1) “Standard”, 1/4″ Thick |

$24.05 | $2,405 | $40,885 |

| Synthetic Composite Shingles (Plastic, Rubber) |

$12.60 | $1,260 | $21,420 |

| Wood Shingles Red Cedar |

$13.95 | $1,395 | $23,715 |

| Wood Shingles Red Cedar Class A Fire Rated System |

$15.65 | $1,565 | $26,605 |

Shingle Roof Cost Factors

The two biggest cost factors for a shingle roof are, of course, labor and materials. For asphalt shingle roofs, the split between labor and materials is typically close to even, around 40% to 60% each. For other types of shingles, that ratio can shift depending on the material and the level of skill required for the installation.

In general, material costs make up a larger share of the total for higher-cost products like copper and slate.

Material Costs

Material costs for a shingle roof are determined by the surface area of the roof, the type and grade of shingles used, and the kinds and quantities of roofing accessories required for the system. Shingle material costs vary widely based on weight, thickness, fire rating, fastening method, and raw material prices.

Accessory materials such as underlayments, flashings, ventilation components, fasteners, and ridge or starter shingles can also vary significantly depending on the requirements of the specific shingle material type.

Labor Costs

Labor costs vary by region, but installation time also differs depending on the material. Asphalt shingles are relatively fast to install and widely used, so labor is generally efficient and consistent. Synthetic and metal shingles tend to take longer due to interlocking panels or accessory-specific details. Slate and wood shingles require installers with a higher skill level, specialized tools, and take more time per square to install correctly, which increases labor cost.

Even for asphalt shingles, luxury or designer shingles may take longer to install due to their weight, thickness, or shape.

Roof Complexity

The more complex the roof layout, the more labor-intensive the job. Valleys, hips, dormers, chimneys, skylights, and intersecting roof planes require additional layout, cutting, and flashing work across all material types. These areas slow down installation and increase labor time, especially when using materials that are difficult to trim and and modify on-site like slate or metal. Complicated roofs also require that a higher waste factor be applied to the job, which gets passed on to the homeowner.

It can take two to three times longer to complete complex roof areas compared to uninterrupted open roof areas.

Roof Pitch (Steepness)

Steeper roofs increase labor costs regardless of the shingle material. A pitch greater than 6/12 typically requires additional fall protection and equipment, which slows down installation. In general, steeper roofs take longer to install and can increase labor costs by up to 50% over a safely walkable roof. For most residential jobs, this can raise the total project cost by 20% to 30%.

Removal of Existing Roofing

Most re-roofing jobs require removal of the existing roof system before new shingles are installed. This is required by code when two or more layers of roofing are already present. Installing the new shingles over the old shingles is called a “roof recover”, and only a roof with existing asphalt shingles will be suitable for this process. Regardless, in terms of the long-term performance, it’s always preferable to remove the existing roof covering before installing a new shingle roof. Roofs installed over an existing roof tend to fail earlier. The only benefit of a roof recover is short-term cost savings.

Tear-off and disposal typically add between $1.00 and $3.00 per square foot, depending on the number of layers, local disposal fees, and roof accessibility.

Permits and Local Fees

Permits, inspection fees, dumpster rental, and disposal charges vary by location and will be included in the total project cost. These fees are usually a small percentage of the overall price, but they will be passed on to the homeowner.

Shingle Roof Components

When you’re calculating material costs for a shingle roof, the shingles themselves are only part of the system. There are several other components that go into any typical shingle roof installation. Some of them are required by code, some are standard best practices, and others may or may not be needed depending on the type of shingles you’re using and the design of your particular roof.

Shingles

- Field shingles – The main shingles that make up the surface of the roof. The size, shape, weight, and installation method varies by material.

- Starter shingles or starter strips – Used along the eaves and often the rakes. Required for most asphalt, synthetic, and metal shingle systems. Some materials, like slate or wood, may use other detailing instead.

- Hip and ridge cap shingles – Preformed cap materials are available for asphalt, metal, and synthetic shingles. For wood and slate, ridge pieces may be custom-cut or installed using separate materials like copper ridge rolls.

Underlayment

- Ice and water shield – A self-adhering waterproof membrane required by code at eaves and valleys in most American climate zones. Used with all shingle types, though especially important under metal and slate where water intrusion risk is higher.

- Standard underlayment – Felt or synthetic underlayment is used under asphalt, synthetic, wood, and some metal shingles. With slate, a heavier base sheet or multiple plies may be used depending on slope and exposure.

Fasteners

- Roofing nails – Common to all shingle types, but the material and size vary. Stainless steel or copper nails are typically required for slate, wood, and some metal shingles.

- Screws – Some metal shingles are installed with exposed or concealed screws instead of nails.

- Staples – Generally not used except with some synthetic underlayments, and usually not recommended or allowed for primary roof covering attachment.

Flashings

- Drip edge – Used along the eaves and rakes on nearly all modern shingle roofs to protect the sheathing edge and fascia by guiding water runoff away from the structure.

- Pipe boots – Used to seal around plumbing vents. Must be compatible with the shingle material and installation method.

- Step flashing – Required where a sloped roof edge meets a vertical wall, used with all shingle types.

- Valley flashing – Metal valley flashing is common with wood, slate, and metal shingles. Woven or “closed” valleys may be used with asphalt shingles.

Ventilation

- Ridge vents and soffit vents – These make up a typical passive ventilation system and are compatible with most shingle types.

- Static vents and roof fans – Used when ridge or soffit venting isn’t practical.

- Gable vents and plumbing vents – These should be accounted for in the flashing and ventilation plan for any roof.

Roof Decking

Any rotten or otherwise deteriorated roof sheathing discovered during tear-off must be replaced before installation can begin. Since you usually can’t tell how extensive this will be, or whether there’s any deck issue at all, this cost is normally included in a roofing proposal as a unit price to be added as necessary during the job.