I participate in the Amazon affiliate program and may earn commissions from purchases made through links on this page.

Table of Contents

Introduction

The pitch, or slope, of your roof affects how well your roof sheds rain, snow, and debris and determines what types of roofing materials are appropriate and can be legally installed. This article explains what the minimum roof pitch is for asphalt shingles, the most common roofing material in North America.

Note: Pitch and slope are not technically the same thing, but I’ll be using the terms interchangeably here. The building code uses “slope.”

Asphalt shingles are part of a roof assembly that includes a solid deck, one or more layers of underlayment, flashing, fasteners, and the shingles themselves. Unlike low-slope roofing systems that are designed to be fully-waterproof barriers, asphalt shingles are water-shedding. They rely on gravity and shingle overlap to keep water out of the roof system by moving it quickly off the roof. If they are installed on a roof that is too flat, water can back up under the shingles, leading to leaks, rotten deck, and possibly mold. This can void warranties, violate code, and cost a lot of money to fix.

If you aren’t sure what your roof pitch is, you can get a very cheap, very accurate slope finder from Amazon. I have one of these and it works pretty well.

Minimum Allowed Roof Slope for Asphalt Shingles

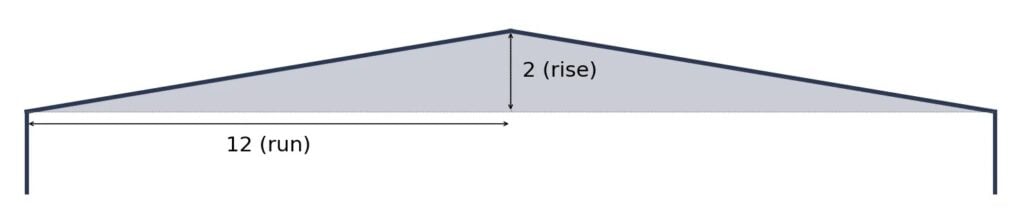

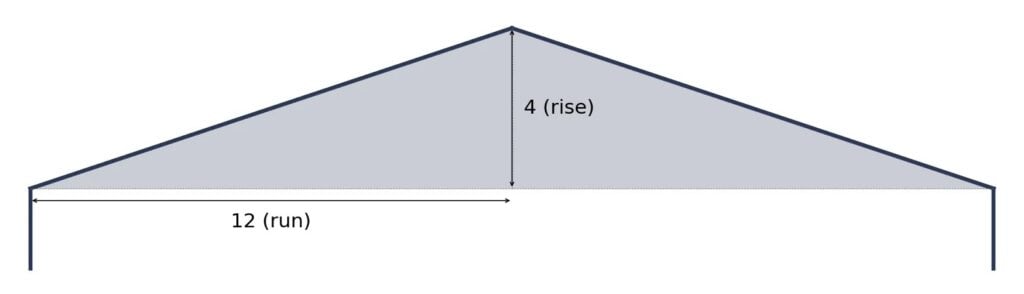

Asphalt shingles can only be installed on roofs with a slope of 2:12 or greater. This means the roof must rise at least 2 inches for every 12 inches of horizontal run. A 2:12 slope can also be expressed as 9.5° slope or a 17% slope. Anything less is a code violation and a very bad idea. On slopes between 2:12 and 4:12, the building code requires a double-layer of underlayment to provide extra protection.

Installing asphalt shingles on a roof with a slope below 2:12 can lead to serious problems. Because shingles are not watertight and rely on gravity to shed water, low-slope installations increase risks from ponding water, ice dam formation, and water intrusion, especially during rain accompanied by high winds. This can lead to saturated underlayment and roof deck, as well as rot, mold, and interior water damage.

Manufacturers explicitly prohibit such installations, so any asphalt shingle application below the minimum slope will void the product warranty. It also violates the International Residential Code (IRC), which can lead to failed inspections, insurance claim denials, and liability issues for contractors.

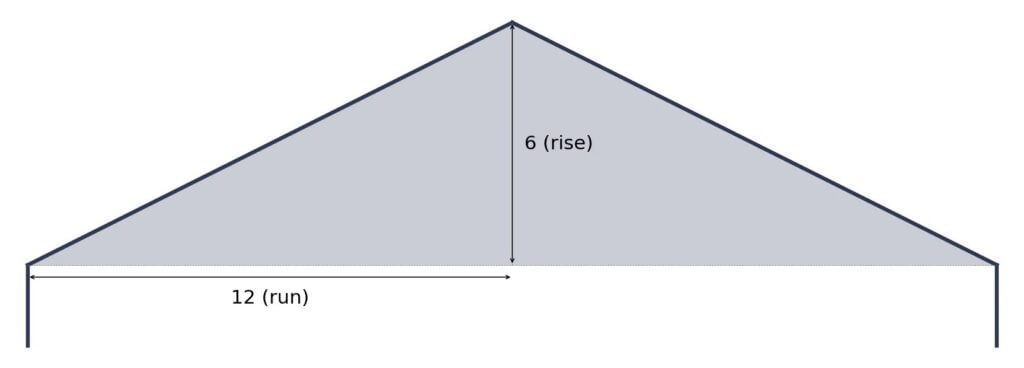

While asphalt shingles can technically meet code at slopes as low as 2:12, they’re really not ideal for anything under 4:12. The fact that the building code requires a double layer of underlayment below that threshold is a clear sign that shingle performance can be expected to drop off below 4:12. This is common sense and confirmed by my professional experience.

Even though it’s allowed, as a roof consultant I would not recommend asphalt shingles for a 2:12 or 3:12 roof. Even when installed correctly, shingles on 2:12 to 4:12 roofs are more likely to leak and suffer from ice dams. If your roof pitch is below 4:12, it’s worth considering whether another material might be a better choice.

If you are going to install asphalt shingles on a pitch below 4-in-12, it’s very important that you hire a highly-qualified roofing contractor who knows what he’s doing. And if your contractor decides to install a peel-and-stick underlayment over the entire roof deck as extra protection against leaks. These underlayments tend to act as vapor barriers, so if you’re using one, you must make sure your attic ventilation is up to or above code so moisture doen’t accumulate in the wood roof sheathing due to condensation.

Better Roofing Options for 2:12 to 4:12 Roof Slopes

Metal Roofing (Standing Seam)

One of the best-performing and best-looking roof systems for lower-sloped residential roofs. Standing seam metal panels can be installed on slopes as low as ¼-in-12 by code (and with manufacturer approval, of course). They shed water effectively, resist ice damming, and have a very long lifespan. They do cost a lot more than asphalt shingles.

Modified Bitumen

Modified bitumen is a common low-slope roofing material, a lot like roll roofing, but it uses asphalt modified with a small amount of plastic or synthetic rubber to produce a much more durable high-performance product. It’s applied in two layers with overlapping courses; this creates a fully watertight roof membrane. Mod bit is surfaced with granules like asphalt shingles and you can often get modified bitumen in colors that can match the shingles on the steeper parts of your roof.

Single-Ply Membranes (TPO, PVC, or EPDM)

Single-ply membranes are typically used on commercial flat roofs, but they can be used for low-slope residential applications too. TPO and PVC come in white, gray, and tan; EPDM is normally black. One drawback of the white membranes is that they really show the dirt (roofs get very dirty). Appearance isn’t normally an issue on commercial roofs, but you might want to think about it if anyone is going to be able to see your low-slope roof.

Code Sections: Minimum Roof Slope

From the 2024 International Residential Code, here’s the section that dictates acceptable roof slope for asphalt shingles:

R905.2.2 Slope

Asphalt shingles shall be used only on roof slopes of 2 units vertical in 12 units horizontal (17-percent slope) or greater. For roof slopes from 2 units vertical in 12 units horizontal (17-percent slope) up to 4 units vertical in 12 units horizontal (33-percent slope), double underlayment application is required in accordance with Section R905.1.1.

And here’s the equivalent section from the 2024 International Building Code:

1507.2.2 Slope

Asphalt shingles shall only be used on roof slopes of 2 units vertical in 12 units horizontal (17-percent slope) or greater. For roof slopes from 2 units vertical in 12 units horizontal (17-percent slope) up to 4 units vertical in 12 units horizontal (33-percent slope), double underlayment application is required in accordance with Section 1507.1.1.

Underlayment Requirements

Here are the underlayment requirements for asphalt shingles just mentioned in section R905.2.2 Slope, including a detailed description of how the underlayment should be installed for slopes between 2-in-12 and 4-in12:

Underlayment Application – Asphalt Shingles (Table R905.1.1(2))

Areas Where Wind Design Is Not Required In Accordance With Figure R301.2.1.1:

Underlayment shall be one of the following:

1. For roof slopes from 2 units vertical in 12 units horizontal (2:12), up to 4 units vertical in 12 units horizontal (4:12), underlayment shall be two layers applied in the following manner: apply a strip of underlayment that is half the width of a full sheet parallel to and starting at the eaves, fastened sufficiently to hold in place. Starting at the eave, apply full-width sheets of underlayment, overlapping successive sheets half the width of a full sheet plus 2 inches. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. End laps shall be 4 inches and shall be offset by 6 feet.

2. For roof slopes of 4 units vertical in 12 units horizontal (4:12) or greater, underlayment shall be one layer applied in the following manner: underlayment shall be applied shingle fashion, parallel to and starting from the eave and lapped 2 inches. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. End laps shall be 4 inches and shall be offset by 6 feet.

3. A single layer of self-adhering polymer modified bitumen underlayment complying with ASTM D1970, installed in accordance with the underlayment and roof covering manufacturer’s installation instructions for the deck material, roof ventilation configuration and climate exposure of the roof covering.

Areas Where Wind Design Is Required In Accordance With Figure R301.2.1.1:

Underlayment shall be one of the following:

1. Two layers of mechanically fastened underlayment applied in the following manner: Apply a strip of underlayment that is half the width of a full sheet parallel to and starting at the eaves, fastened sufficiently to hold in place. Starting at the eave, apply full-width sheets of underlayment, overlapping successive sheets half the width of a full sheet plus 2 inches. Distortions in the underlayment shall not interfere with the ability of the shingles to seal. End laps shall be 4 inches and shall be offset by 6 feet.

2. A minimum 4-inch-wide strip of self-adhering polymer modified bitumen underlayment complying with ASTM D1970, installed in accordance with the manufacturer’s installation instructions for the deck material, shall be applied over all joints in the roof decking. An approved underlayment complying with Table R905.1.1(1) for the applicable roof covering shall be applied over the entire roof over the 4-inch-wide membrane strips.

3. A single layer of self-adhering polymer modified bitumen underlayment complying with ASTM D1970, installed in accordance with the underlayment and roof covering manufacturer’s installation instructions for the deck material, roof ventilation configuration and climate exposure of the roof covering.

Note that the second part of this (Areas Where Wind Design Is Required) applies to geographic regions where buildings must be engineered to withstand higher wind forces due to increased risk of strong winds. These areas include designated hurricane-prone regions, coastal high-wind zones, and areas like mountain foothills and tornado-prone zones.

The language in the code means that the double underlayment requirement applies to all roofs, regardless of slope, in these areas. Increased roofing fastener requirements will normally also apply in these areas.